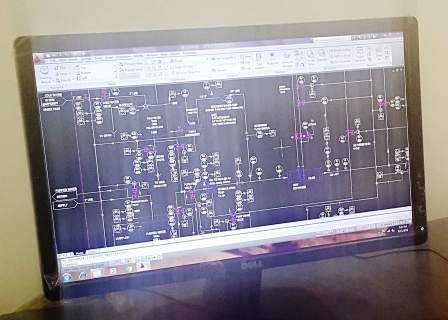

Stanseals has an in-house design and development team operating the latest 3D and 2D Computer Aided Design (CAD) technology

The design team create both standardised, modular sealing and system solutions as well as bespoke engineered client specific solutions each to exacting standards and international specifications.

We invent and create innovative solutions for demanding applications and thus have established ourselves as a leader in the designer of systems for use with an number of water and oil based fluids, including;

- Purified water

- Glycol solutions

- Synthetic organic fluids

- Silicone fluids

We also provide full process system design, create process methodology, schematic layouts and help clients select the right process equipment for their desired outputs whether it is for a pilot plant, research and development lab or production plant upgrade.

Stanseals offer a complex range of value-add services, starting at the Design stage, as follows;

Design & Customisation

- URS (User Requirement Specification) - Client specific design and product configuration (DQ - Design Qualification)

- 3D CAD model develop and client exchange and PAT (Process Analytical Technology)

- Equipment modularisation - future-proofing your operations with incremental 'bolt-on' modules as your business needs develop.

- Operator ergonomic testing for sustainable operation, maintainence and access. Also tests to ensure all system areas are cleanable (CIP/SIP)

- Full client engagement and design specification (DQ) sign-off before manufacture commences