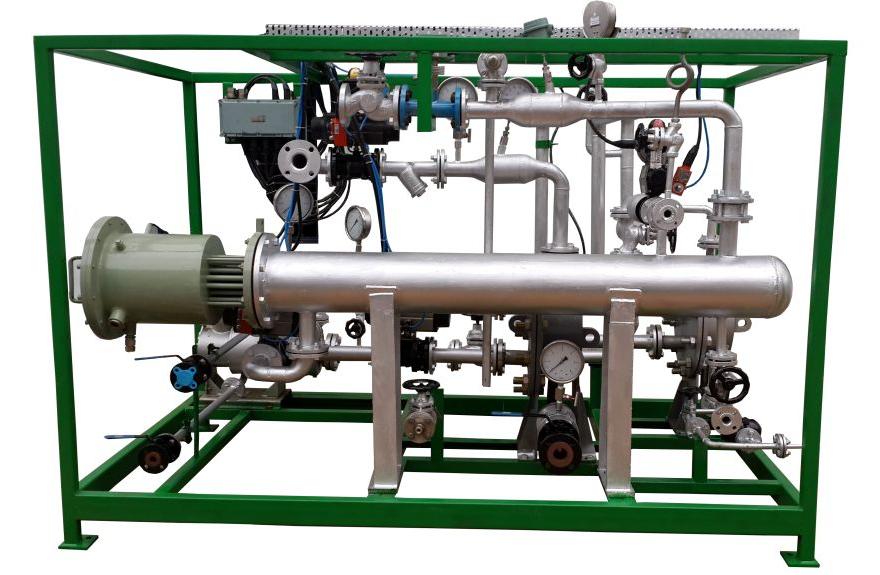

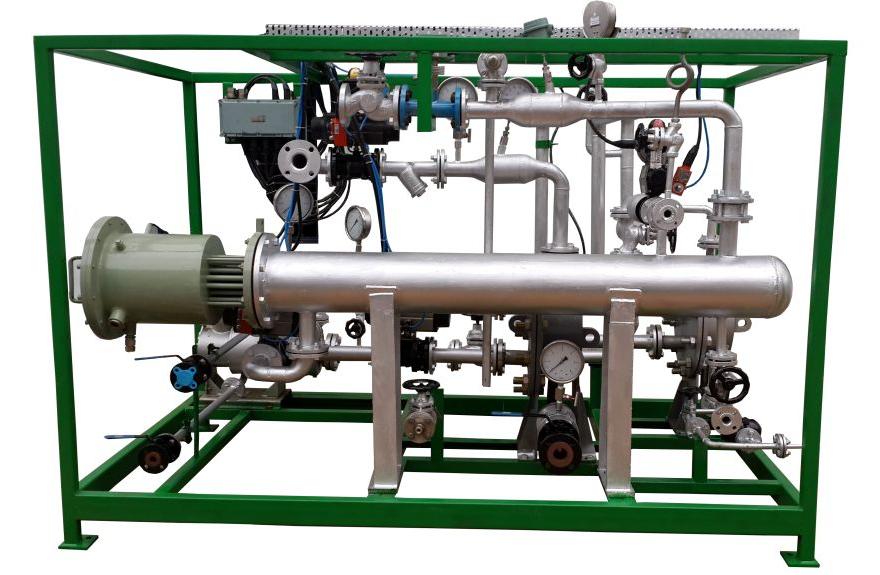

Stanseals design, manufacture and install single fluid heating systems (SFHS) in a number of standard and bespoke configurations.

Stanseals design, manufacture and install single fluid heating systems (SFHS) in a number of standard and bespoke configurations.

Heating systems are used in the manufacture of Bulk Drugs, API & Fine Chemicals and Batch processing. Typical Stanseals system application duties include;

- Individual hot thermal fluid generator – Temperature up to 300°C (572°F)

- Combined clean hot & cold thermal fluid generator – Temperature range -100°C to 300°C (-148°F to 572°F).. (SFHCS model)

Our Single Fluid Heating and Cooling Systems (SFHCS) solutions have a multiple advantages over the conventional multiple utility systems, especially for Batch processes as outlined below.

Design Features

- Designed to Current Good Automated Manufacturing Practice (cGAMP)

- Full PLC control for operational reliability

- Tamper Proof - Electronics closed in lockable cabinets

- Record and retrieve the isolator operation data.

- Multilevel password protection for Isolator operation, maintenance and control

Operational Benefits

- Stable, reliable and accurate results

- Clear visibility of system operational performance: Digital display, lights & alarms

- Operation safe

- No changeover between different utilities avoids cross contamination.

- Non corrosive and clean fluids means “ No Corrosion” and “ No Scaling”

- Thermal fluid having wide temperature range can be selected to provide flexibility.

- Single pipeline for Fluid Inlet and Outlet to process area reduces chances of leakages.

- Non water based utilities reduces risk for water reactive processes.

- Accurate temperature control to ±1°C can be achieved.

- Automated continuous temperature control without any interruption for changeover possible.

- Fast heating and cooling profiles can be achieved, reducing batch time.

- Programmable ramp based heating and cooling possible meeting requirement of critical processes like crystallization.

- Smooth temperature changeover avoids thermal shock to equipment as well as products.

- 21 CFR compliant Data logging possible for regulatory compliance.

Applications

- Thermal Control Unit Control

- Reactor Control

- Process Equipment performance management

- Batch reaction

- Distillation

- Crystallisation

- Hydrogenation

- Drying

Stanseals design, manufacture and install single fluid heating systems (SFHS) in a number of standard and bespoke configurations.

Stanseals design, manufacture and install single fluid heating systems (SFHS) in a number of standard and bespoke configurations.